INTRODUCTION:

“Khurja is known across the globe for its sheer poetry in clay.”

— S M Khan, Khurja pottery expert and historian

While eating in a fancy restaurant, have you ever looked at your plate carefully? There is a high possibility that the aesthetic ceramic plate must belong to Khurja. Pottery art is one of the oldest traditional art forms. In which objects are made from clay and fired with heat. There is a rich cultural history behind the advanced or skillful artistic techniques which is evolved in the local regions by millions of artists. Indian artists have been practicing pottery-making for centuries. The oldest evidence of pottery dates back even before the Indus Valley civilization. Khurja has been a center for making ceramic pottery and artistic objects for years. Khurja is located in the Bulandshahr district of Uttar Pradesh. Khurja is also known as “the Ceramic City of India”.

KHURJA: CERAMIC CITY

Natural advantages of Khurja make it the ceramic hub of India. Khurja has a rich soil profile as it’s located in the Yamuna doab near Delhi. Khurja pottery has always been accessible to the royal or Urban population of Delhi, which maintains its demand in the market. The rich clay of the region provides suitable raw material to the artist to shape the clay into beautiful artistic and decorative art.

ROOTS IN CLAY: A HISTORICAL PERSPECTIVE

The History of this craft dates back 600 years. It is believed that pottery artists of Egypt and Syria traveled with the Afghan invader Timur Lung and brought their skill to Khurja. Others also trace its roots to Muhammad Bin Tuglak in the 14th century and the Mughal period. The Mughal patronized the artists and contributed to the growth of the craft. Khurja pottery is the fusion of Mongol, Persian artistic techniques with the Indian aesthetic touch of local art.

Colonial power took it differently by focusing on maximum production rather than crafting innovative masterpieces. They introduced new modern technologies, which resulted in revolutionary advancements in pottery making and led to the production of more. But they replaced the traditional method of wood-fired kilns with coal kilns.

After Independence Government introduced policies and programs to transform and support the years-old craft and artists. Modern artisans, combined with traditional methods, brought tremendous growth in the pottery town.

CRAFTING PROCESS

Clay: This is an essential raw material. Various types of clay powder, such as quartz clay, phosphate clay, Bikaner clay, and porcelain clay, are mixed with clay flour.

Plaster of Paris: Plaster of Paris, or POP, is used to make molds for casting ceramic objects. It uses water, and the object takes shape.

Oxide Chemical Colors: These colors are used to add color to objects processed with iron, cobalt, chromium oxide, etc. These colors are mixed with a glaze solution and applied to objects; this reaction can be observed when heated, producing the desired color.

Glaze Solution: This solution gives the object a shine. Furthermore, it imparts a beautiful color and texture to the finished object.

Kiln: It helps heat objects after they have been formed.

Jigger and Jolly Machine: This machine creates small objects using molds.

VARIETY AND MOTIFS ON PRODUCTS

Ceramic potteries are prepared for retail and bulk orders. Due to digitalization, and internet makes it easier to customize the designs or shapes as per the demand and interest. There is availability of a variety of art pieces under the category of ceramic pots, Kitchenware, Decorative art items as flower vases, table lamps, bathroom accessories, dinnerware, cups, plates, bottles, containers, planters, classic pots, gift items, art ware, crockery ware, Electrical products, Sanitary wares, tiles, and household products.

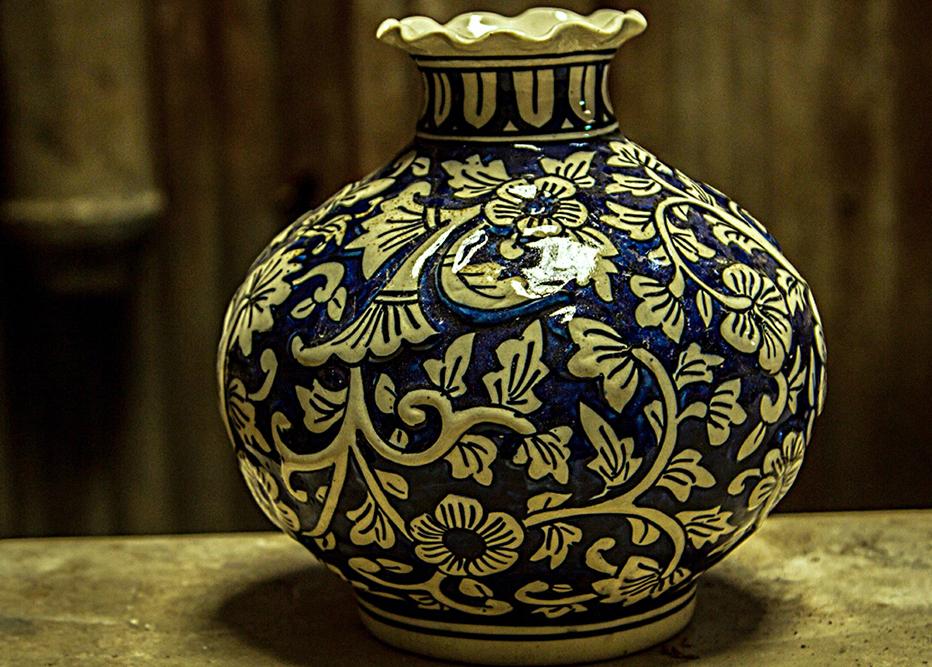

There are two types of painting on ceramic pots, one is Mughal art, and another regular painting with motifs on the exterior surface. Mughal art is painted with a cobalt-blue color and a colorless lead glaze, whilst sketching designs like as floral or geometric patterns on the outside surface using oxide colors and a colorless lead glaze is another genre. Ceramic objects painted on a plain surface. It adds value and makes it distinct from other pottery. Artisans use squirrel-hair brushes for motifs like peacocks, paisleys, and Mughal jaali patterns. Sticker ornamentation is another method of design on ceramic products like coffee mugs and crockery, mainly used for better aesthetics for marketing.

PEOPLE BEHIND THE POTTERY

That knowledge and skill of making creative, artistic pottery was transferred from one generation to another. There are 15000 government employees and 25000 informal laborers to mold clay into the masterpieces. Nearly 500 units work in the 400 factories. The younger generation is excited to carry forward the legacy and knowledge of their ancestor. They won the national awards for their innovative idea in the craft. A skilled artist from Khurja won the national award in 2017. Another award was won by Akhtar Ali who learned the art from his father. Most notable winners in the list are Mr. Prabhul Prajapati 2008, Ram Kumar Prajapati 2007, and Mr. Kailash Prajapati 2003. The story of these potters shows the humble beginnings of Khurja’s renewed artisans.

MARKET OF KHURJA POTTERY

Khurja pottery industry employs twenty thousand people, including artists. Labors and traders. This also generates new jobs in the related sectors, such as transport and retail shopkeepers etc. With the rapid awareness of the eco-friendly products increased the demand for ceramic pottery has increased to replace the fiber plates. People’s obsession with aesthetics due to social media influence also promoted the aesthetic ceramic potteries to be used in the kitchen and for decoration. High rated restaurants also use ceramic crockery to serve their dishes to maintain their aesthetic vibe.

The global interest in handmade, eco-friendly and artistic ceramic products has increased. It boosted India’s ceramic export industry. Khurja attracts buyers as we as tourists interested in traditional and hand-made pottery. Digital platforms have expanded the reach of Khurja pottery by making it available to an international audience. E-commerce and digital marketing enable the artisans to sell their products in the global market. Its unique design and natural material attract domestic as well as international customers.

CHALLENGES

The industry faces several challenges that hinder its growth and competitions. Machine made ceramic pottery is cheaper than handmade pottery. Chinese items have flooded the market and making it difficult for handmade potters to compete. Not all industries have access to modern machinery, automated processes, and eco-friendly glazes. It affects quality and durability. So some artisans still use traditional kilns and methods, which take a long time and lower efficiency, resulting in higher cost. Fuel and electricity costs for electric kilns increased production expenses and reduced profit. All required raw materials as high-quality clay, colors, and glazing materials, are becoming costly and scarce. Many small-scale artisans lacked the knowledge and resources to market their products online or globally. There is no proper branding and certification system, which makes it harder for Khurja potters to establish a strong identity in the market.

Although government-run programmers such as the One District One Product (ODOP) scheme promote Khurja pottery, and to provide funds and subsidies. But it does not always reach small artisans. Many pottery businesses have to struggle to obtain loans and financial assistance due to the long and complicated process. Traditional pottery production methods contribute in the spread air pollution. There is a lack of awareness about sustainable practices makes it hard to adopt eco-friendly methods.

REVIVAL EFFORTS

The government is developing ‘ceramic haat’ under the Khurja Master plan 2031, for maximum benefit. Workshops and exhibitions in national and international trade fairs promote the Khurja pottery. Digital marketplaces (Amazon, Flipkart, and Export Hubs) provide better reach to customers worldwide with special prices and delivery at the doorstep. The government is focused on saving water in the pottery-making process through water recycling and water conservation goals to achieve SDG 6.

CONCLUSION

The government must provide financial support and easily accessible loans to support newly emerging factories and small firms. They also need to run a training workshop to train the artists to practice the sustainable and eco-friendly method of pottery making. The government should develop an infrastructure and a market accessible to sellers and buyers. Growing global demand indicates its bright future for the ceramic pottery industry. Khurja pottery can be a contributor to the economic growth of India to become a developed nation by 2047, for the government needs to overcome the challenges. Khurja pottery preserved the years-old legacy and culture.

References

- https://www.incredibleindia.gov.in/en/uttar-pradesh/khurja-pottery

- https://shop.gaatha.com/indian-craft-blog/famous-arts-and-crafts-Uttar-Pradesh?srsltid=AfmBOoqdU1JFsiWn97diEYXjgCzvJ5v6_FeMWChnezLG21AIoIv-EoNr

- https://itokri.com/blogs/craft-masala-by-itokri/history-of-pottery-art-in-india?srsltid=AfmBOooayC_VGgIXKQBs1sSIq5KAwT8XQJvobPDb-ASgYJ3nWbPJOL0s

- https://www.k-the-hidden-story-of-indias-pottery-paradise/

- https://www.khurjapotteryhub.com/history-of-khurja-pottery/

- https://hindikrafts.com/khurja-pottery/

- https://www.socialresearchfoundation.com/new/publish-book.php?editID=10834#:~:text=The%20pottery%20industry%20is%20an,with%20increasing%20awareness%20of%20sustainability.

- https://www.dsource.in/resource/ceramics-khurja/process/casting/mould-making